The goal of this project was to design three gears from scratch which would allow for a 4:1 gear ratio to turn a flag into a precise position.

Modeling

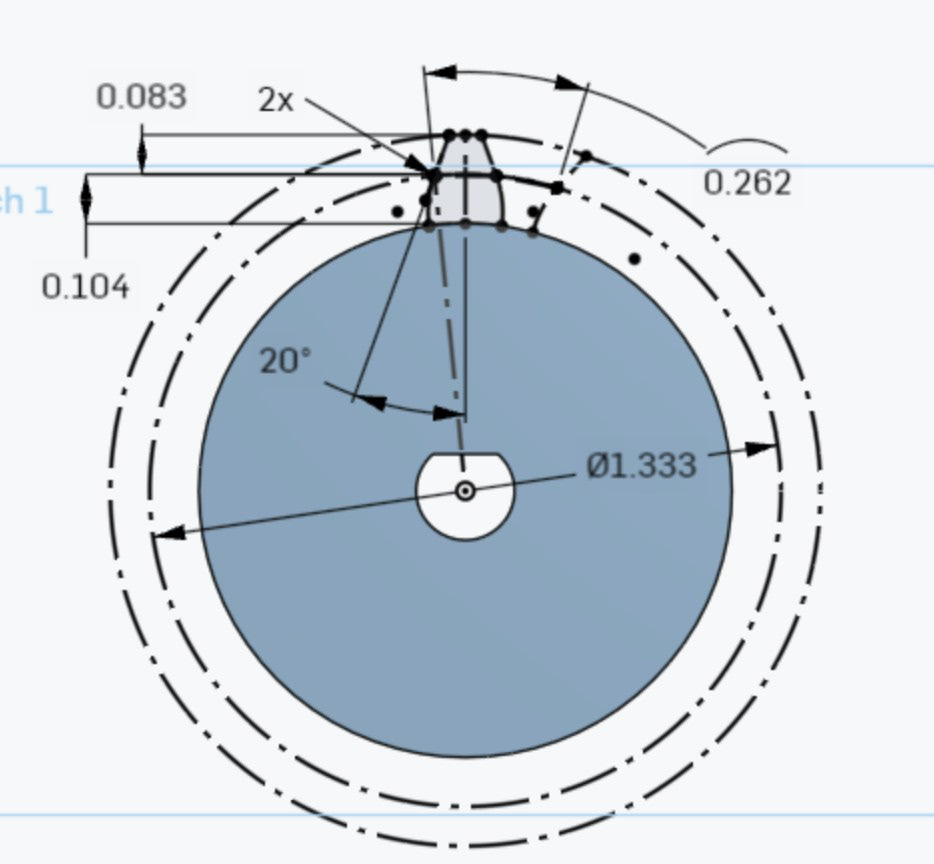

Much of the work involved in this project came with the CAD modeling of the gears themselves. As described in the group project, three group members had to make gears independently of one another that would, in the end, mesh together and allow for fluid movement. The group agreed upon the number of teeth, diametral pitch, and pressure angles, and the gears could be modeled fully with those specifications. I designed the driving gear, which would be the smallest.

A mockup layout for how the three completed gears would mesh together.

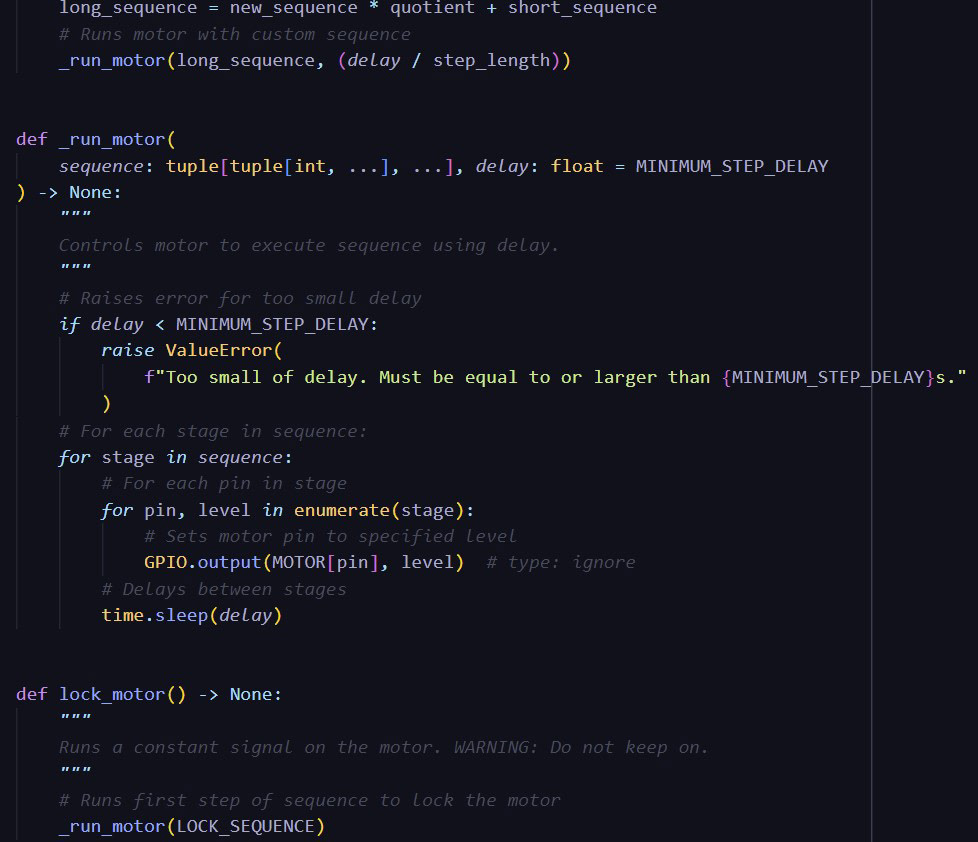

Code

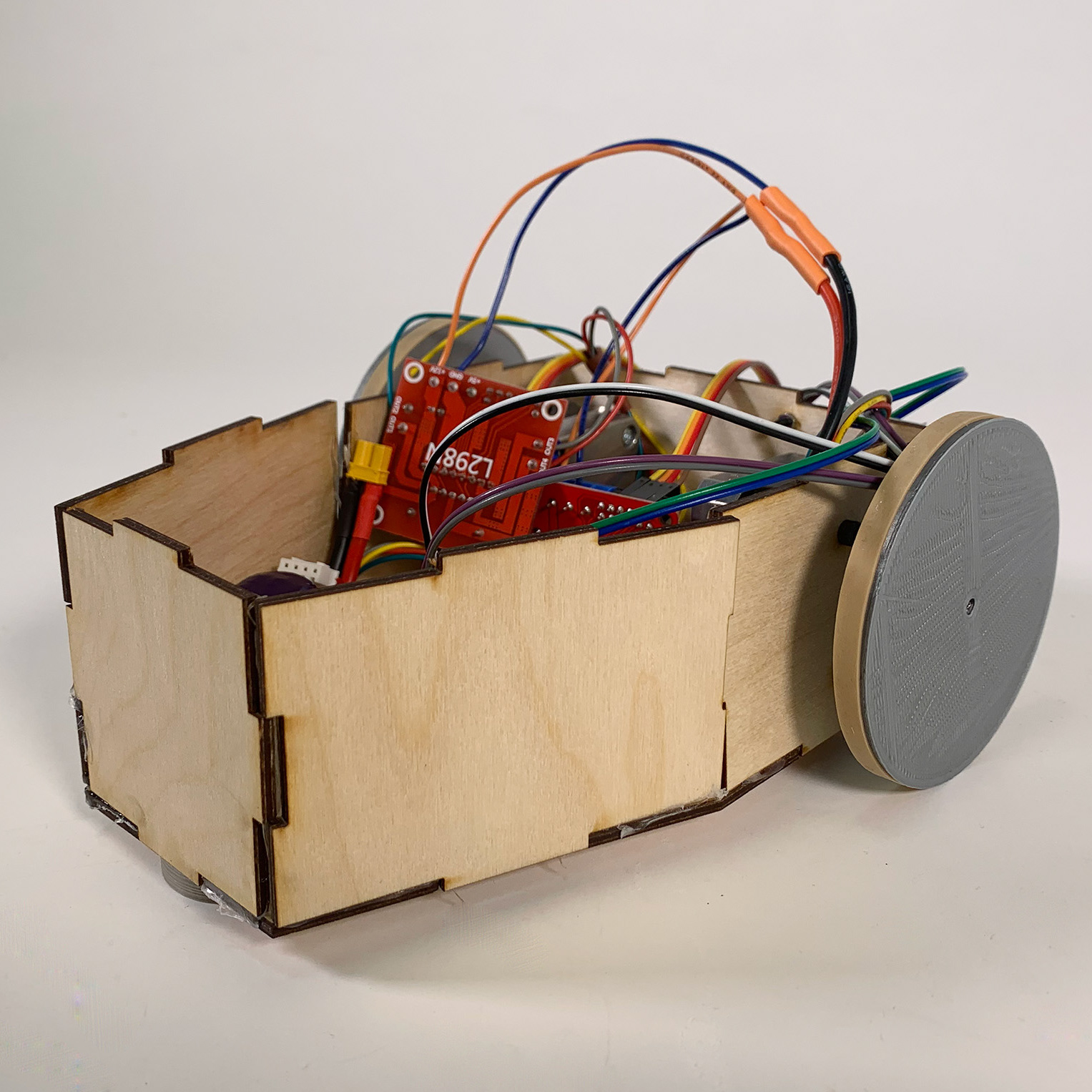

I developed code that would allow for the rotation of a stepper motor using a custom half-or-whole step sequence. It allows for future compatibility with multiple motors, directions, and sequences. The full repository can be found here. The code was run on a connected Raspberry Pi, which communicated its commands to L298N H-Bridge.

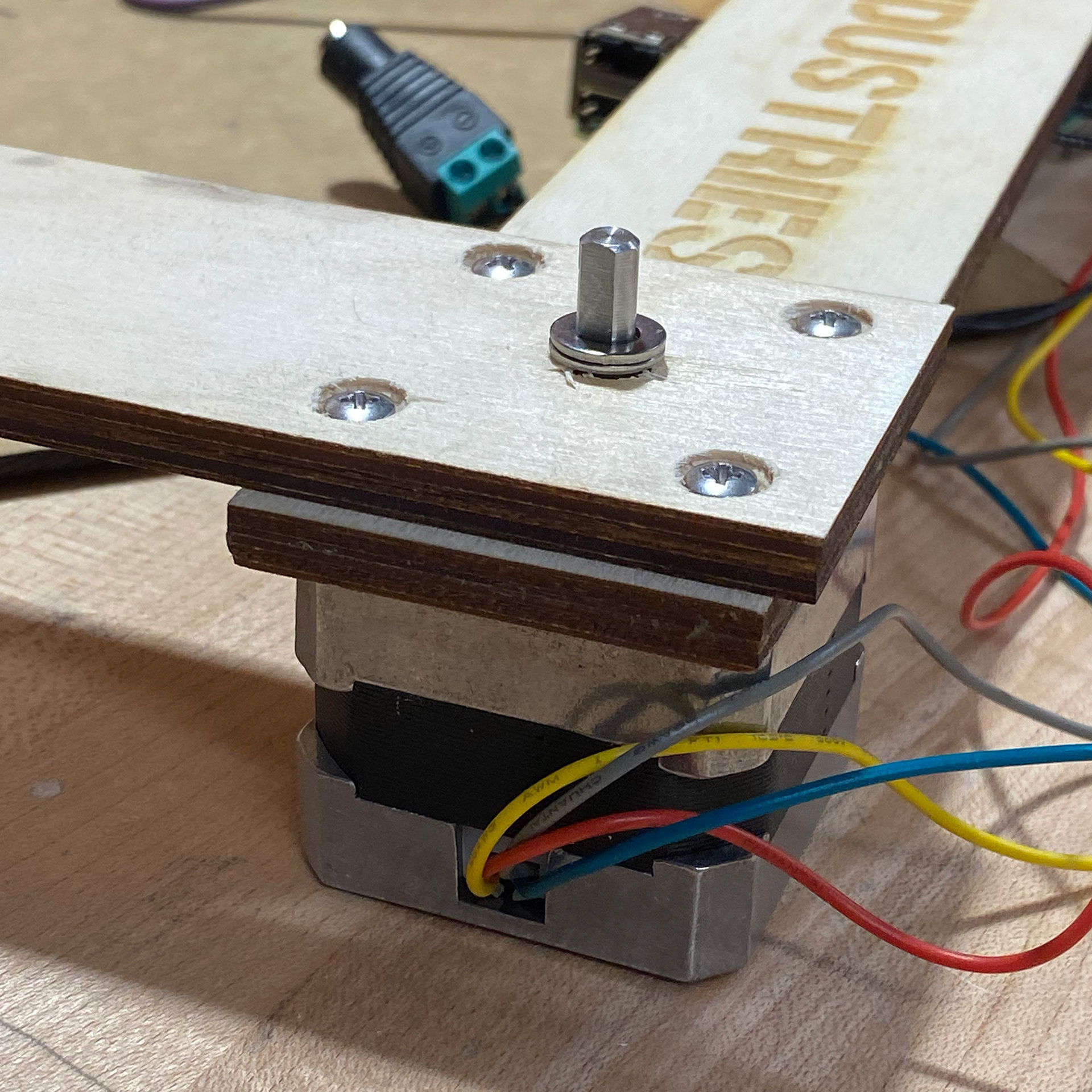

Support Plate

Finally, we needed to design a support structure onto which we could mount the fabricated gears and stepper motor. I designed a vertical plate with foot supports, and a flag was designed and attached to our largest gear as an indicator. Our goal was to rotate our flag to within one degree of vertical, which we were able to meet. The gears were laser-cut from cast acrylic and the plate was cut from birch.