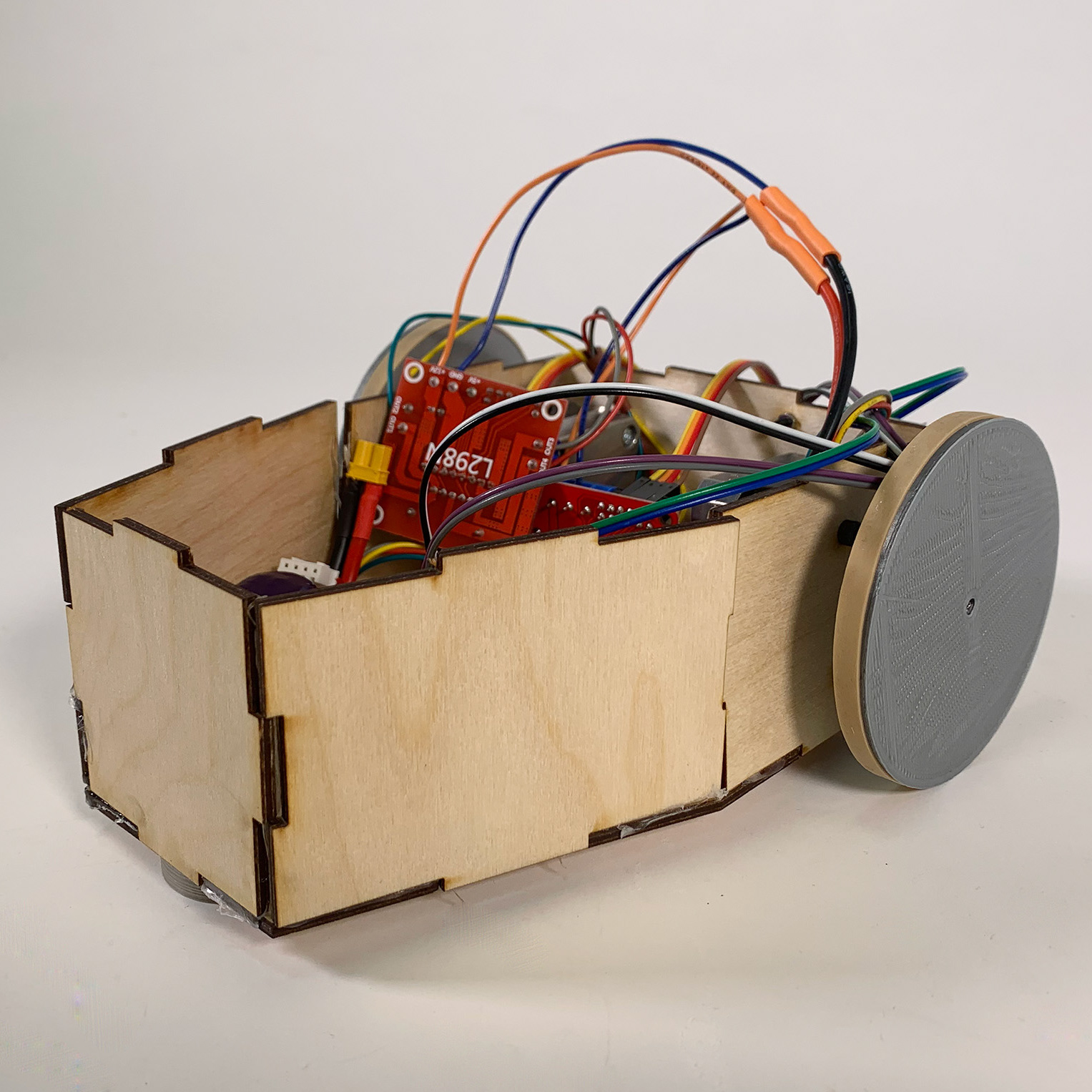

The goal of this group project was to use a series of robots to take an empty cup and create a smoothie from scratch, ready to serve.

Ideation

Our first task was to create a plan of attack in terms of how tasks could be delegated. Larger sub-teams were made, that consisted of Movement, Processing, and Interfacing. This meant a group of people could work together on specific tasks and communicate their needs and adjust to those of the other teams. I eventually became part of the processing team, which was then split up into even smaller ingredient groups. I worked with another teammate on the banana processing.

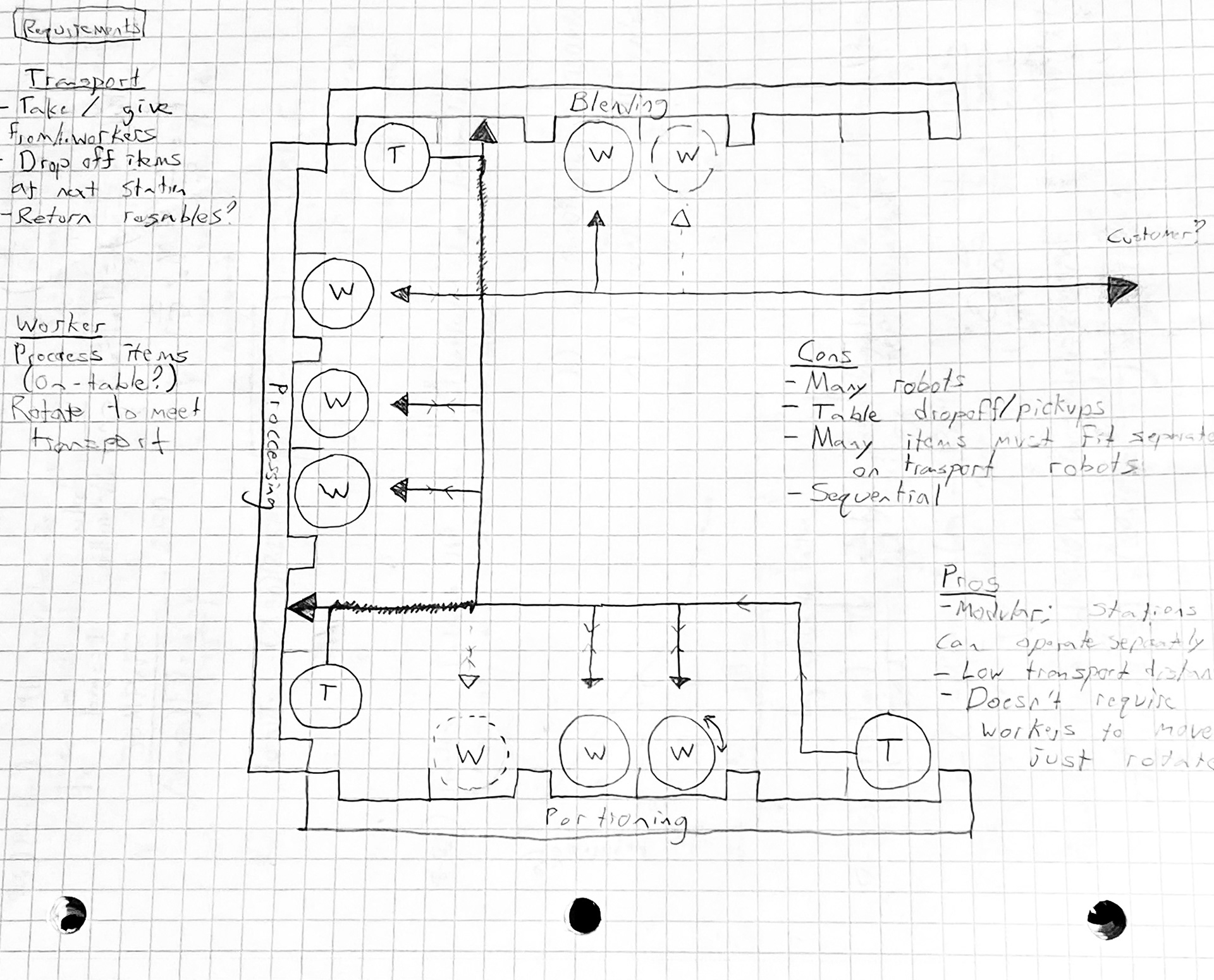

To start the task, we came up with a few ideas about how to lay out the entire process from start to finish. We knew we needed to use a specific series of tables and had access to the iRobot Create3 robots, so I created an initial layout that involved transport robots that would bring ingredients from one station to the next, using a series of drop-off stations.

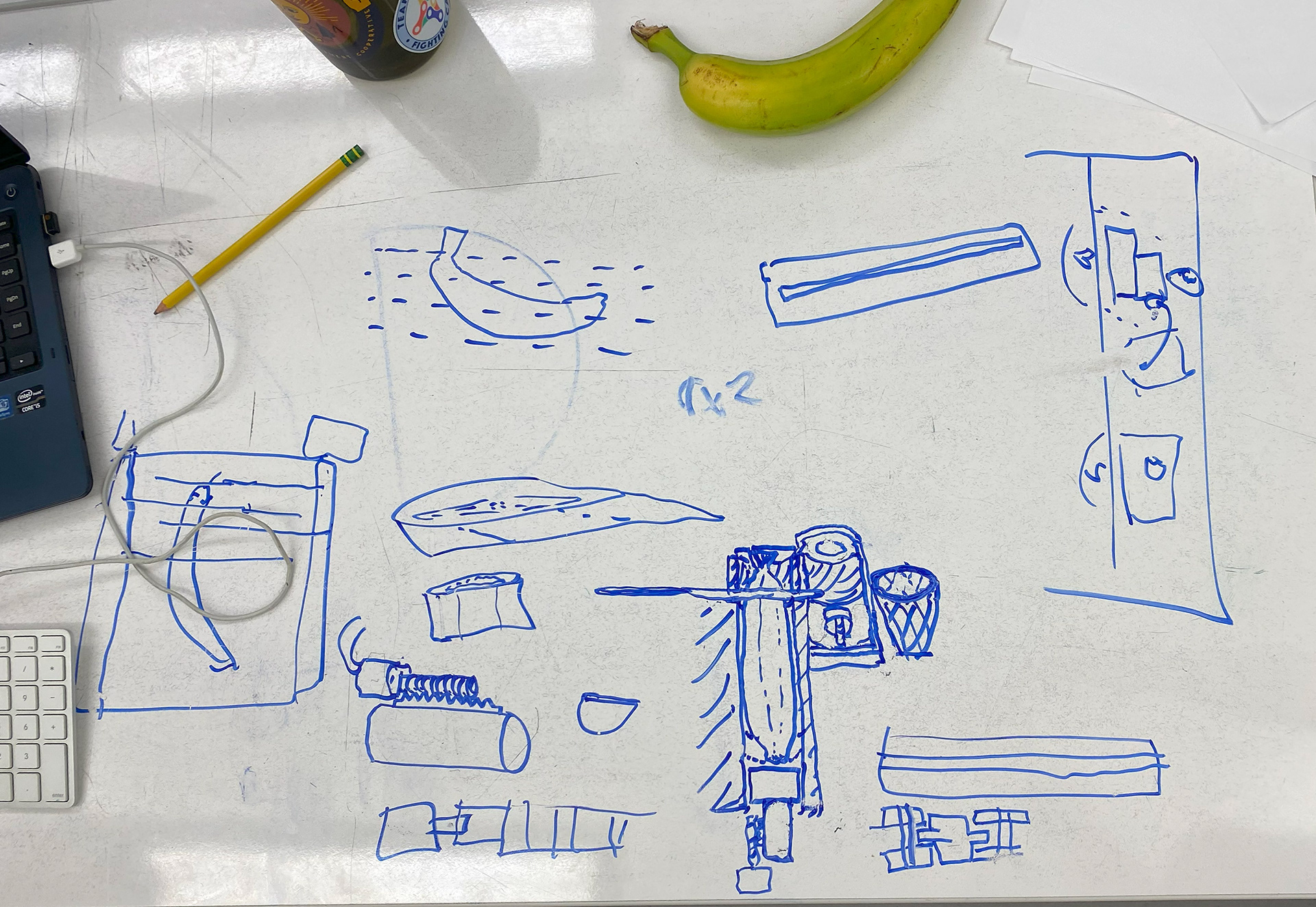

We then began to tackle our specific task of separating the banana from the peel and slicing it

An initial drawn layout for the robot movement.

Some rough drawings for how to create a banana processor.

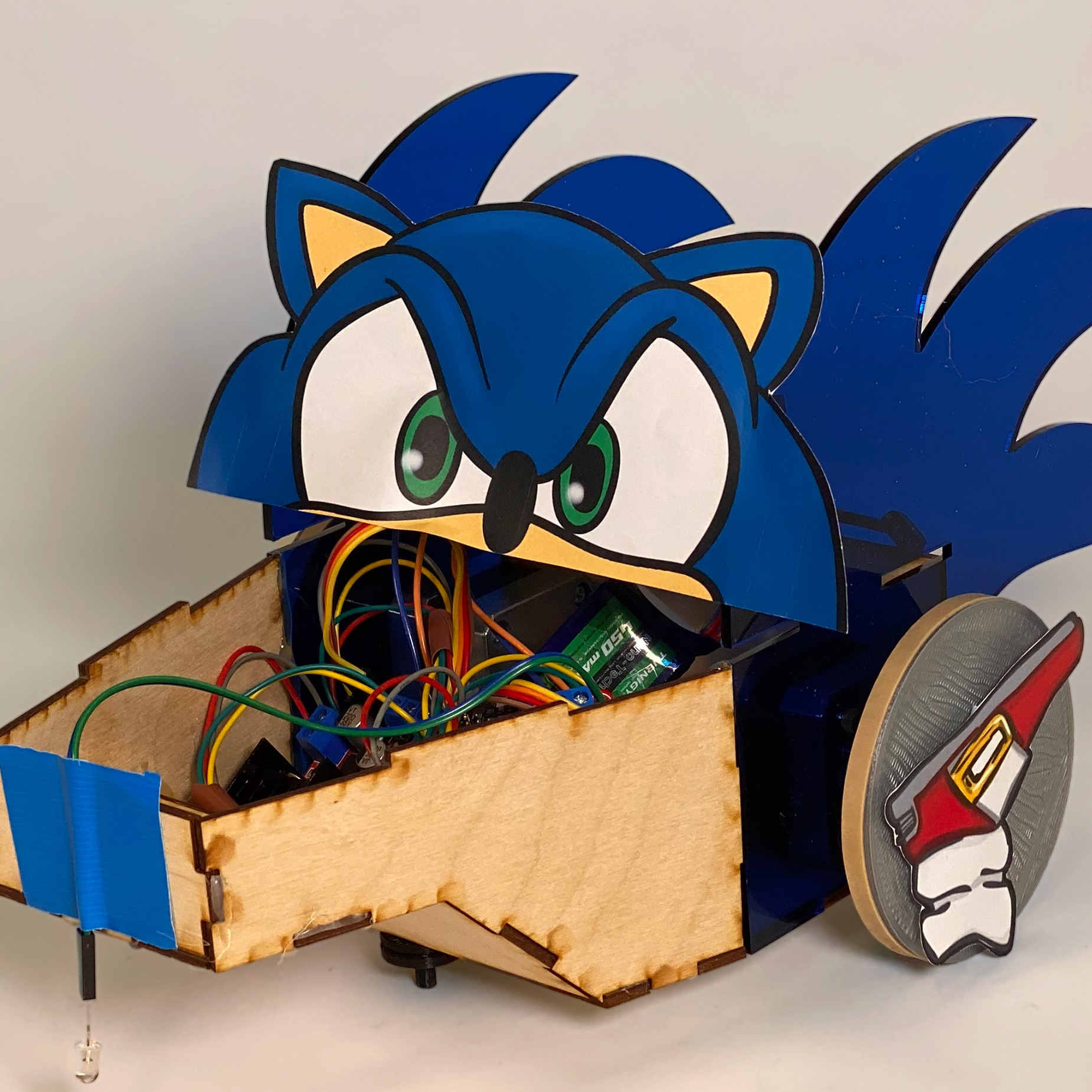

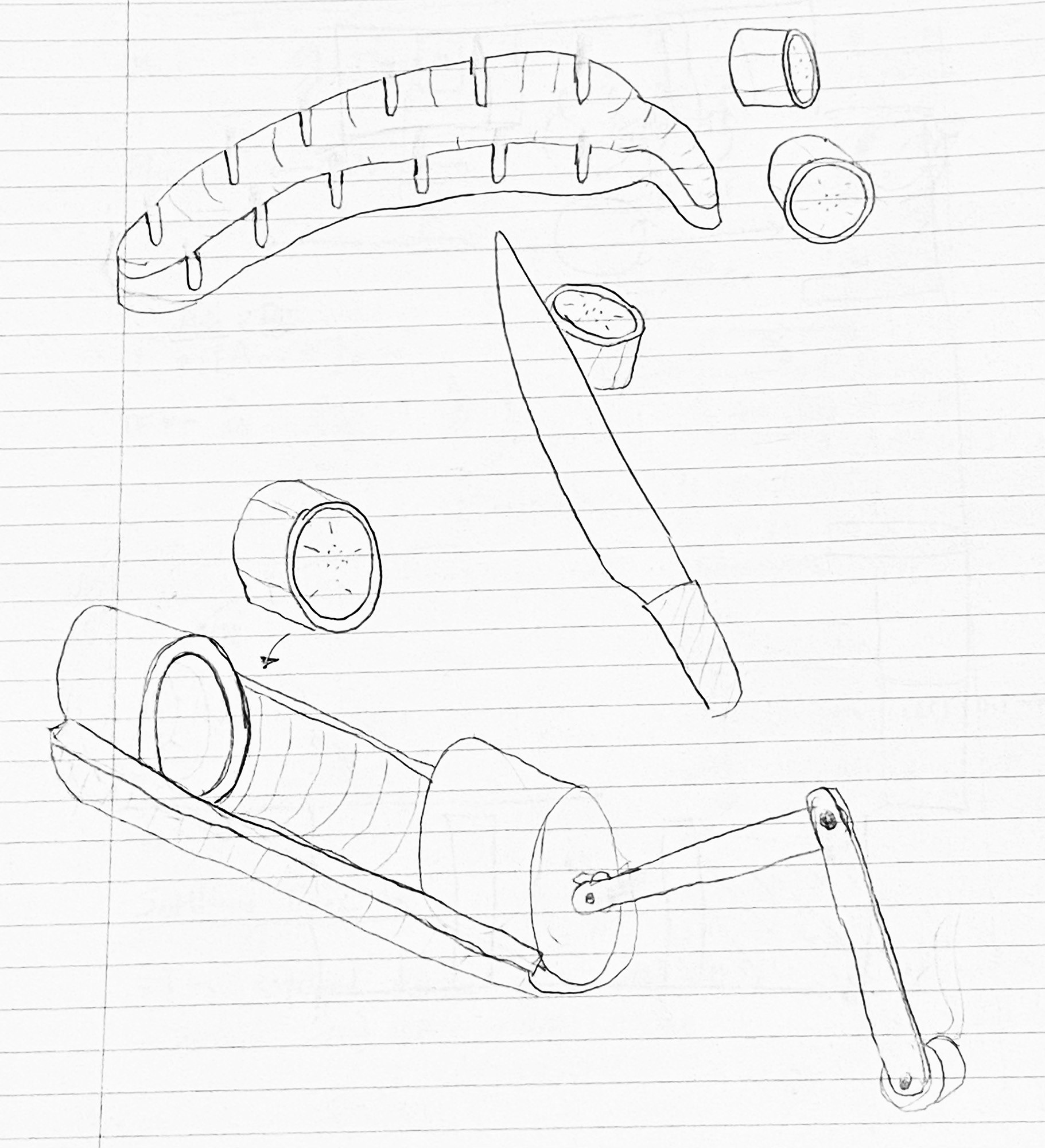

First Design

Our first design attempted to take on both tasks at once. The banana would be loaded into a chamber, and a knife could be used to create a slice, peel, and all. This slice would be lifted by a "flipper" to another chamber, at which a "plunger" would punch out the soft banana inside from the peel and deposit it into a chute. Then, the remaining peel would be discarded with another flipper, Finally, a linear actuator or screw would advance the banana forward and the process would begin. After some initial testing, this design proved to be slightly over-complicated, so the design would later simplify.

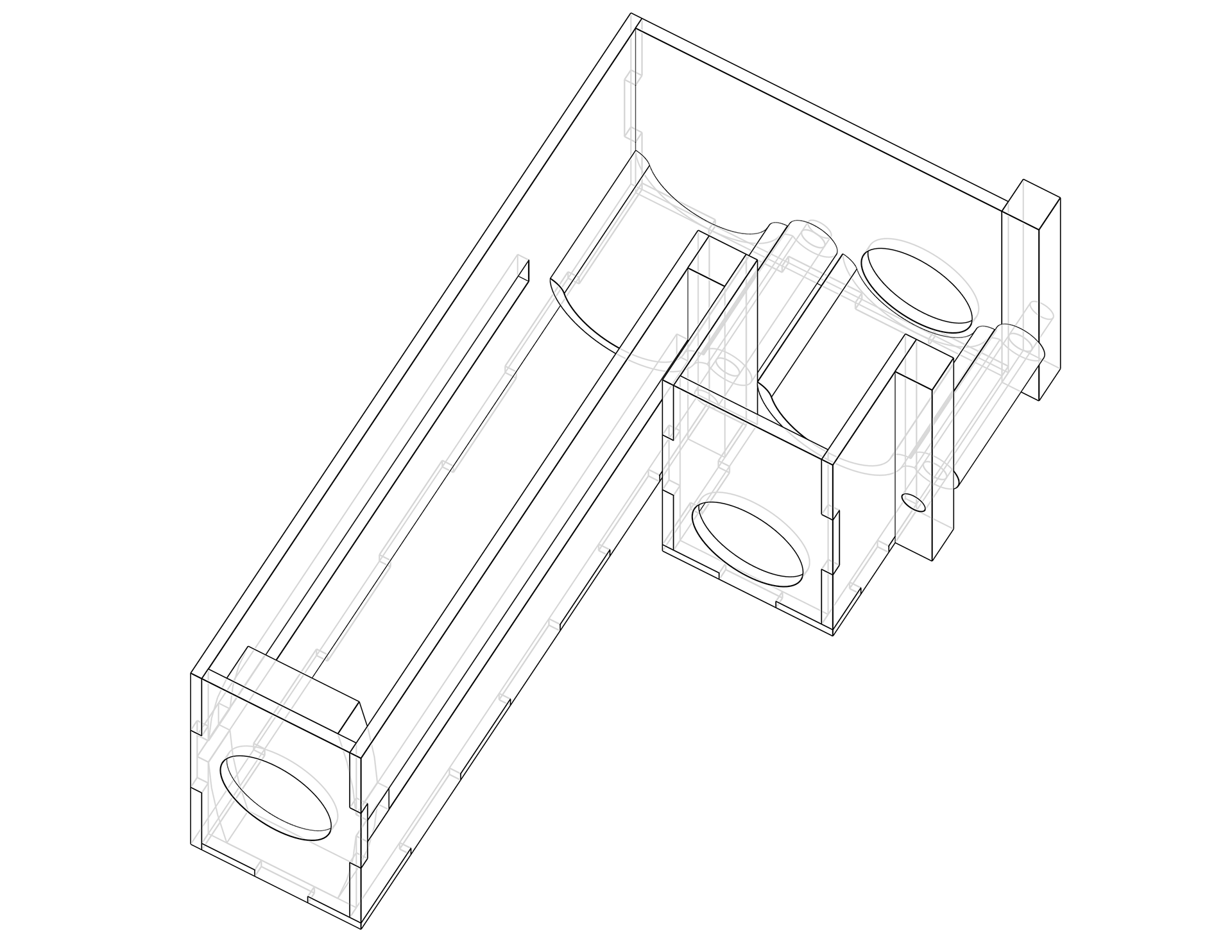

A wireframe showing the old design

A render of the old design

Secondary Design

Our second design got rid of the peeling portion of the process, meaning the bananas would need to be pre-peeled before being placed into the chamber by the transport robot. This simplified a lot of the process, by getting rid of the two flippers and the secondary plunger. As soon as we had this model in place, we began the fabrication process by laser cutting the walls and 3D printing the necessary parts.

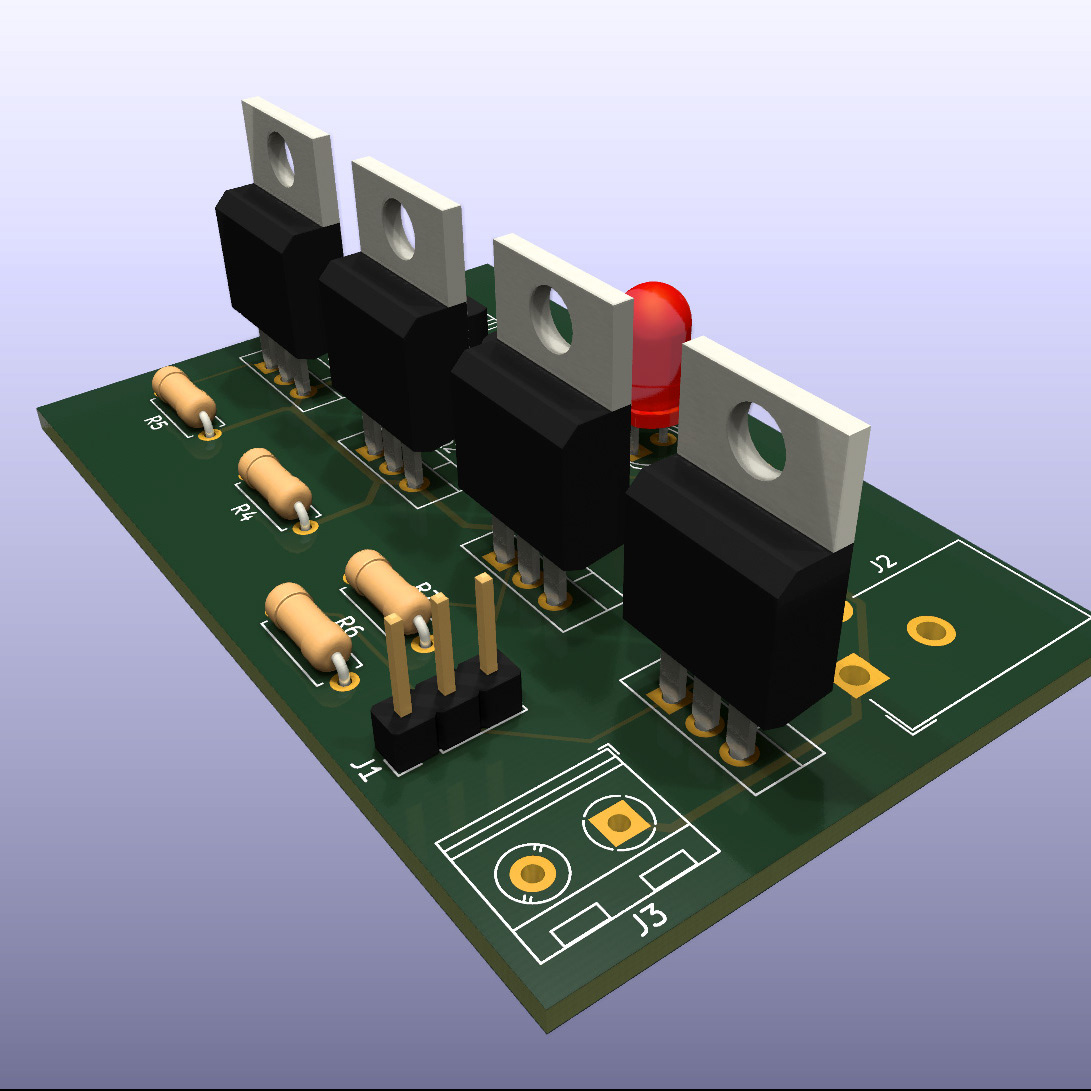

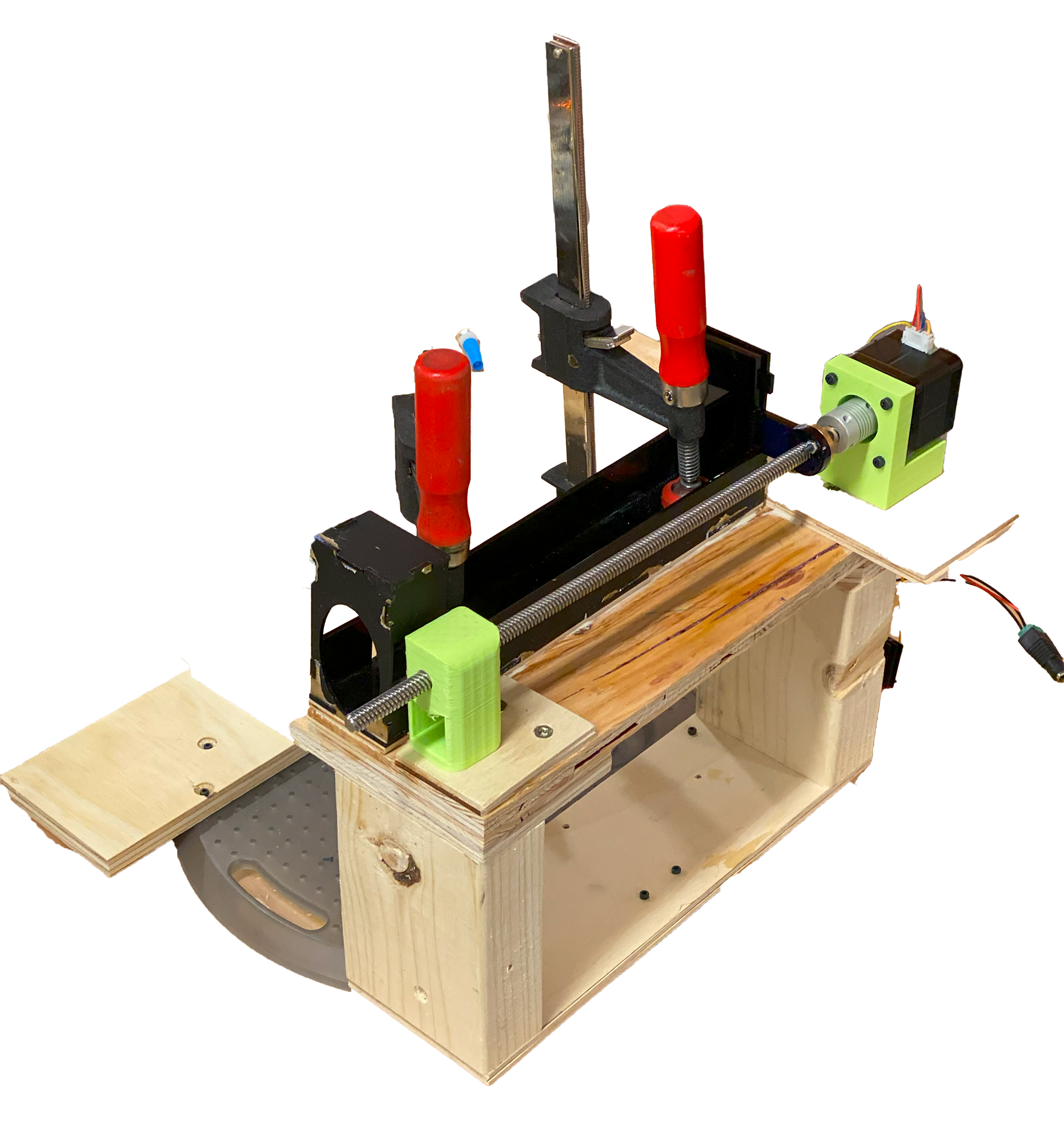

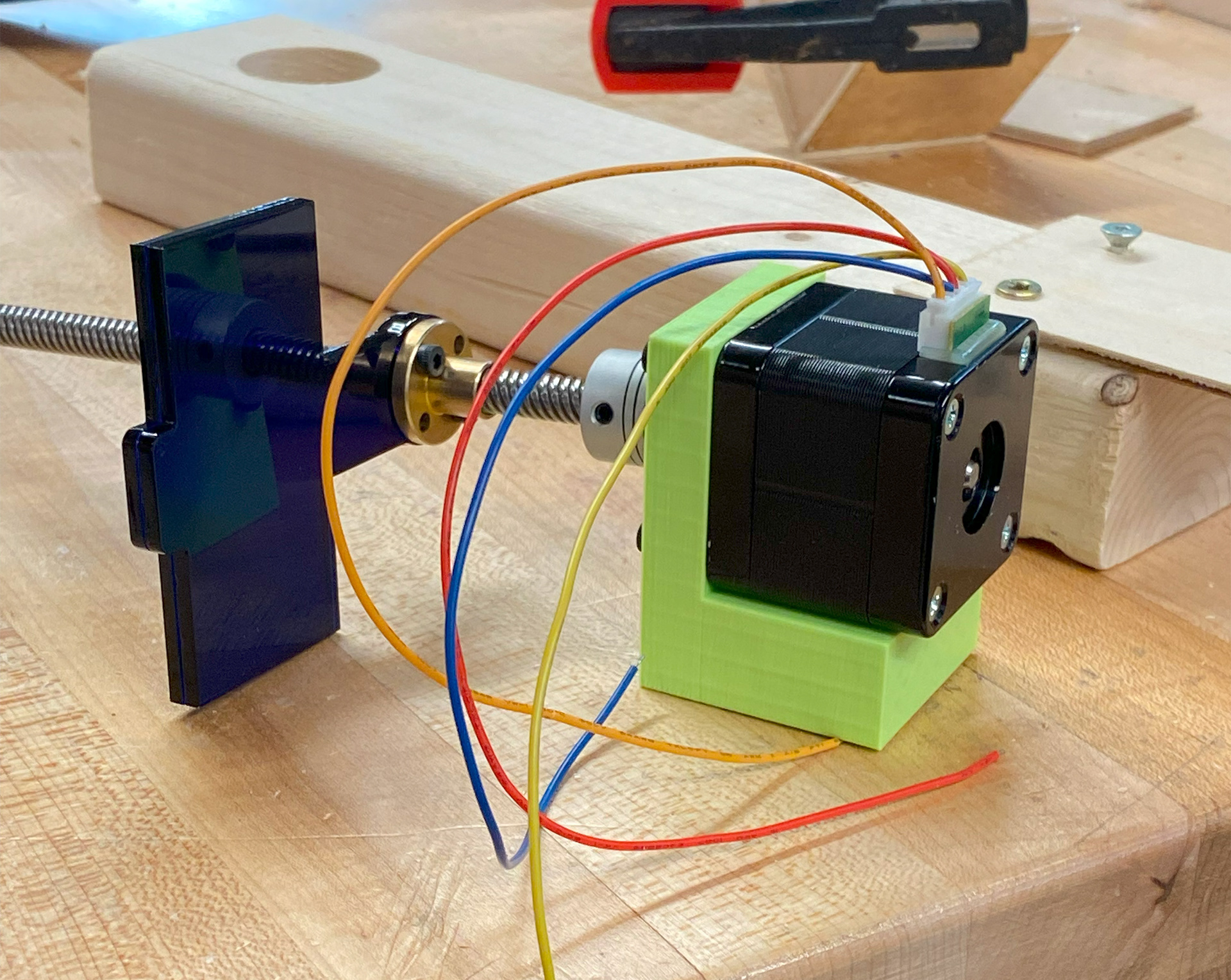

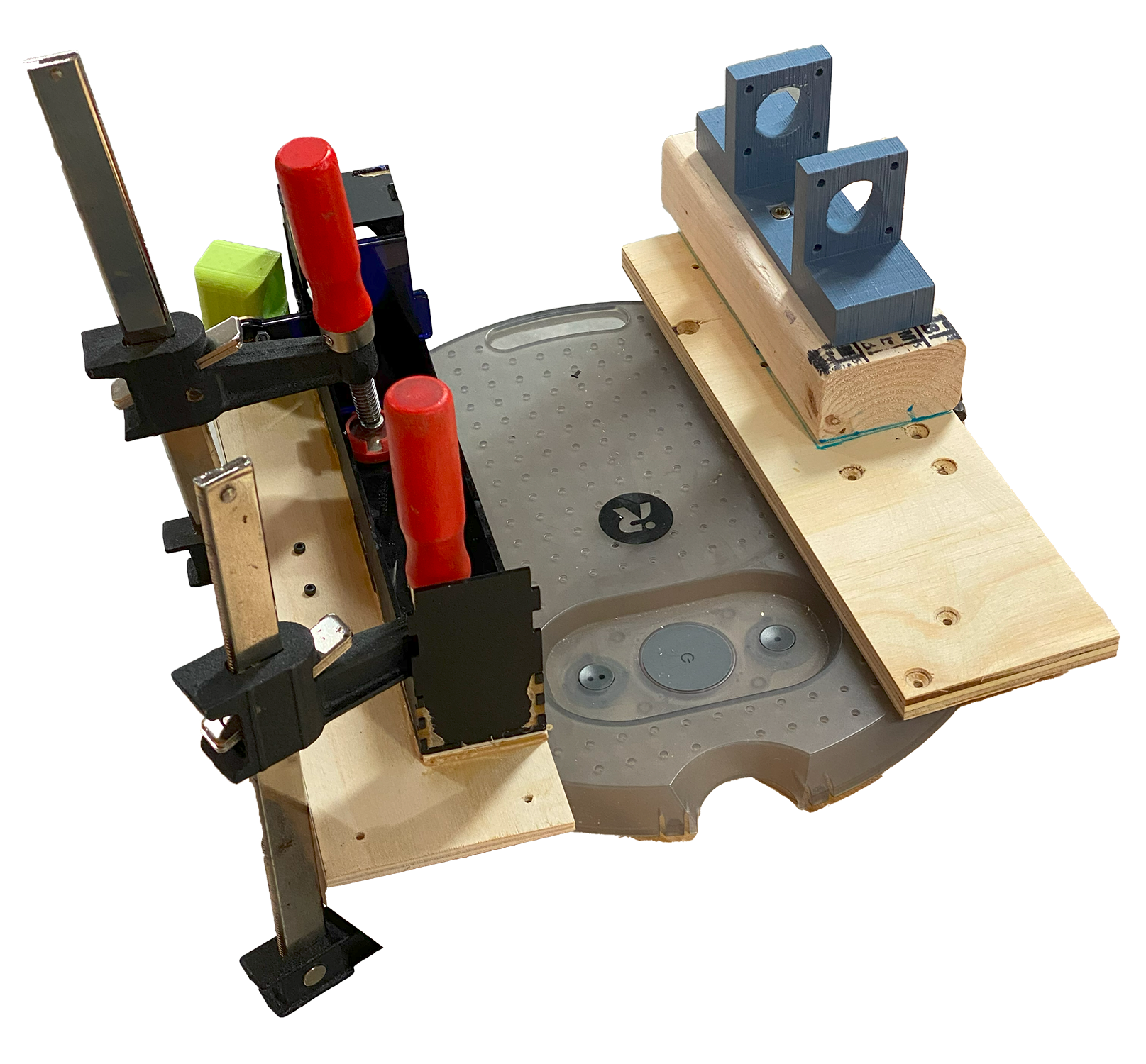

Mounting

We needed, by description of the project, to have all moving parts take place on top of the Create3 robots. This meant everything needed to be built to attach to the top plate. We attempted to build a support that gave the loading chamber vertical height, only to realize that it could not be reached by the transport robot. After some slight iterations, we brought it back down and created a small housing for the knife, in which two stepper motors could be attached via clamps to swivel it up and down.

A small layout test was performed to ensure the correct heights were met for the ingredient transport robot.

Finalizing the Café design

After final testing, we realized the system needed to be simplified even further. To do this, we took the number of tables down to one, reduced the amount of processing and blending robots, and re-created our API. Our first design used an Airtable API to communicate a large amount of data between all of the Create3 Robots, which often meant the same logic was running in multiple places, often overwriting itself and causing errors. I re-created the database allowing for minimal use, in which only necessary data was stored that NEEDED to go from the transport robot to the rest, and vice-versa. The code I wrote to do this and to control my processing Create3 robot is available here.

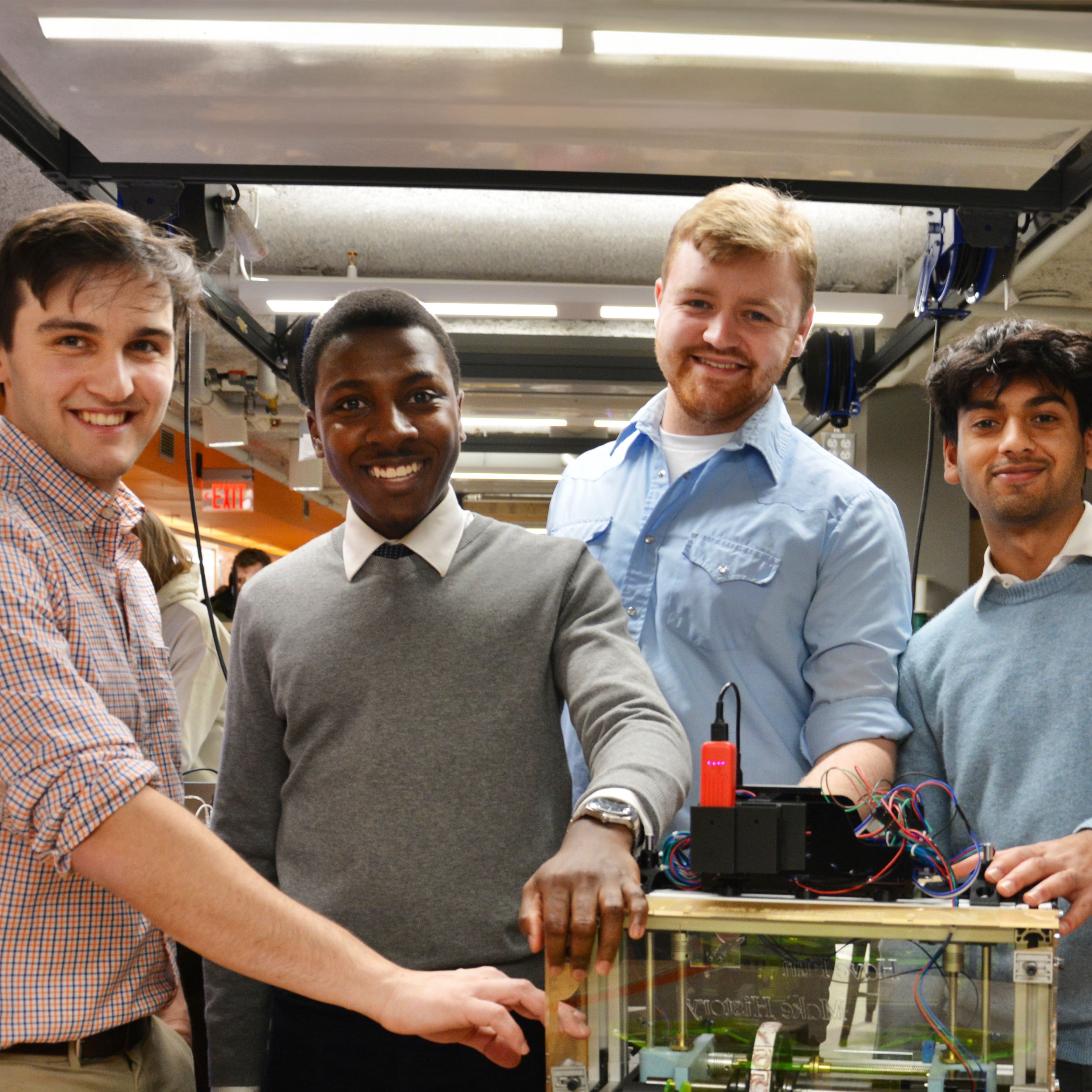

Presenting

Our final presentation took place at the 2023 Boston Robotics Summit & Expo, where we transported our café, set it up for display, and showcased its capabilities. This posed its own set of challenges due to the environmental changes, including doing many hotfixes on the spot. However, we were able to get the café functional by the time of evaluation.